Digital maps drive FairPlay in the cleaning industry

- ulfgullstedt

- Dec 13, 2022

- 4 min read

The cleaning industry has many challenges, but above all great opportunities ahead. Operationally, together with our customers, we have digitized all basic processes. It provides a total overview in real time and quickly becomes the new normal for the four actors involved:

Those who buy

Those who sell

Those who perform

Those who use the premises

Untruths and cheating are destroying the industry. A cleaner Sweden requires professional procurement from both sides. In order to break the myths in the industry and at the same time be profitable, there are a number of hacks that everyone must succeed with. The most important thing is, among other things, to be able to quickly agree on the right pricing for the agreed quality and frequency right from the beginning of a contract where the parties are in agreement. The solution is digital maps.

The correct pricing for the contracted service is determined at the beginning "Many times when a relationship between customer and supplier goes wrong, the respective parties only seek solutions for their own, not for the common, gain. Then there is rarely a winner. - Ulf Gullstedt, CEO of Avista Time

Price, time and quality are connected like three sides of a triangle. Even when you intend to clean. If all parties start from the same information, it is easier to estimate the work effort required to achieve the expected quality. This does not happen when the details of the project-details are incomplete, lack information or are out of date. How and when should what be cleaned by whom?

Step 1: Divide the surfaces

Step 2: Describe the surfaces

As a buyer, you have a professional responsibility for contractual pay and should share the harvesting rate and actual time spent from the previous supplier, if available. What the previous agreement cost is irrelevant. The need may have changed. The quality, perhaps the frequency was not achieved according to previous agreements, possibly due to the wrong conditions?

Step 3: Classify the surfaces

It is difficult to calculate and price the necessary work effort for expected quality per surface without a complete and up-to-date agreement-basis. The better the agreement-basis the supplier receives from the procurer, the more accurate the calculation will be. Together, they can verify the work input for different quality levels. It is likely that the right time is budgeted right from the start before this time is priced.

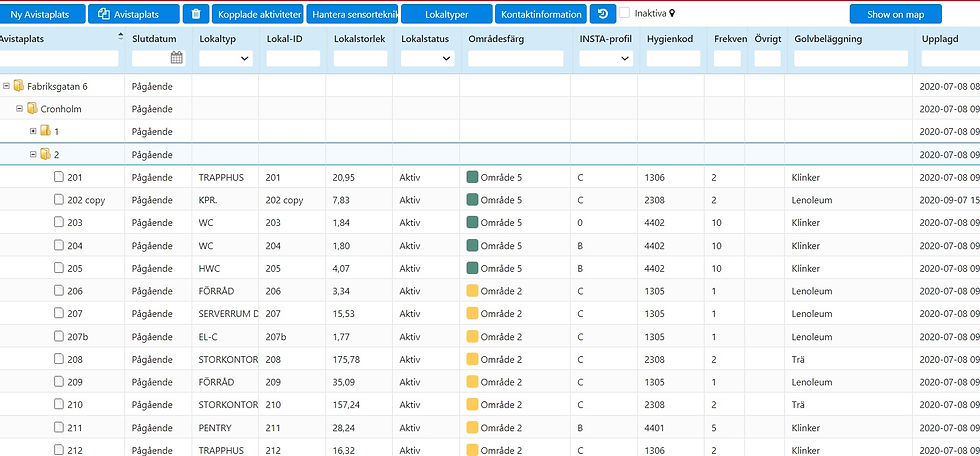

Step 4: Consolidate basic data into the first version of a local register that can now be calibrated and priced!

How much time is realistically required to perform the right quality of what? We now have basic data and accumulated experience to start from.

Step 5: Follow up delivery time! If historical data is missing, it will therefore be a guess in the buyer's market. What is a good or reasonable balance between time-per-quality and type of surface? Therefore, a preliminary study and/or calibration period is recommended. Doing a preliminary study and measuring actual time consumption and possible deviations is today easy if you use digital tools that automatically produce up-to-date and correct documentation for both parties. We highly recommend this. Get it right from the start! In other industries, such as the IT industry, with Service Level Agreements, a calibration period is sometimes applied during the first period to see how much time it actually takes to achieve a certain quality per type of surface. Is the time reasonable? How much over-delivery versus under-delivery? Update the local register? Adjust budget and or contract?

Step 6: Follow up delivery of quality Digital maps should be drawn up and refined continuously before each agreement. If the budget for the assignment is too small, the frequency (time) per surface and/or the quality requirements must be lowered to achieve the right price. A dialogue about the right pricing is always controlled by the buyer. An incorrect estimate of time from start always creates an unprofitable contract for the supplier, before it has even started. With the possibility of digitally describing the assignment, it becomes easier for the parties to estimate the actual degree of work

Step 7: Adjust the agreement within budget Together, buyer and supplier within the same budget can adjust the agreement regarding frequency, quality and scope. When the same variable comes up, the parties may have to agree on an expanded and/or renegotiated contract. If it cannot deliver within a reasonable budget, "Fair Play" is in the danger zone.

Step 8: Become a winner together With the right data from the start, a good contract and feasibility study will basically be the same project. If this is done right from the beginning, the contract reflects the basic operational schedule from the beginning. Buyer and delivery have the same data, but look at it from different angles. Avista Time has digitized all operational processes for the cleaning industry. It represents the new normal. There is no viable alternative to this today. The alternative is worse, costs more and leads to conflict. What is digital can be analyzed, which leads to increased productivity and continued innovation. Everyone must have the right conditions to do a good job. We want to help you create and sign good contracts.

Contact us for more information! - The Avista Time Team

Comments